Sawmill Alignment

Straighter boards, higher output, longer lasting equipment

![]() Visit the new Brunson Alignment Services website here

Visit the new Brunson Alignment Services website here

Optical Alignment

Innovators in the lumber industry are adopting the tools and techniques used by the paper, steel and power generation industries for precision alignment of their equipment. It's called Optical Alignment and is favored among professionals who need precise, verifiable results.

Read our Sawmill Alignment case study

The Basics

A precision optical instrument called a jig transit is mounted on a stable platform. The transit's line of sight is aligned with reference targets. This produces an accurate and repeatable reference used to align all machine components. All measurements are made using tried-and-true visual optical techniques that you can see, understand and verify. It's simple and very accurate.

|

|

The Precision of Optics to the rescue

You'll appreciate the easy set-up, simple operation and consistent performance of the Optical Alignment experience. The work moves quickly and the highly precise results bring a long list of advantages and benefits, not the least of which are:

- Saws cut straighter for longer periods… less maintenance, more uptime.

- Reduced deviation improves output quality and provides more value from every board foot.

- Thin kerf saws run better and increase output volume without increasing wood costs.

- Better alignment means less vibration, which translates into less wear and tear on machinery.

- Improve processes on all machine centers, including hard to align headrig and overhead end-dogger carriage systems.

Training is Available

Never worked with optical instruments? We want you to confidently and successfully use your Brunson Optical Alignment solution. That's why training and ongoing support is available for every sawmill alignment tool kit. And, if you'd like to study Optical Alignment theory in more depth, we offer week-long courses that can take place at our facility in Kansas City, MO or at your place of business.

It Pays for Itself

Customers tell us that our systems pay for themselves within months, with cost benefits continuing to grow after that. The system is simple and the results are precise. Alignments are easily managed by your own people on your schedule. We provide both the equipment and alignment service so that if your alignment requirements are for periodic alignments only, or “as required”, we can provide that as part of a scheduled service engagement only.

If you'd like to learn more about how optical instruments function in a real-world sawmill setting, read “A Closer Look” below and feel free to contact our experts to discuss your specific situation.

A Closer Look

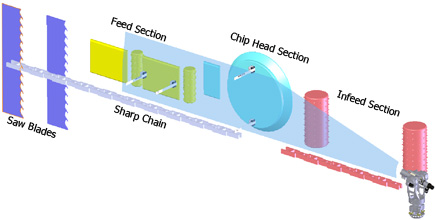

Figure 1: A Jig transit is aligned to the sharp chain centerline and sweeps a vertical plumb plane to measure all cutting section components. |

Figure 2: A precision scale is mounted to the band saw blade to allow plumb, straightness and centerline measurements. Real-time adjustments can be made during the process. |

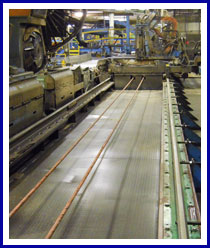

Figure 3: Machine rails must be precisely level to assure the carriage feeds the log straight through the Head Rig band saw. |

The Brunson model 771-H190 jig transit measures straight within .002" (.05 mm) from 34' (10.4 m) away in horizontal and vertical planes… no wires, no plumb bobs or levels, nothing to plug in. Real people view and verify the results, not computers. Plus it generates repeatable data, which is critical to ensure your machine adjustments are correct.

Here's how it works. The machine centerline is defined by the sharp chain that delivers logs and cants to the cutting section. A jig transit is aligned to the sharp chain centerline (Figure 1) and sweeps a true vertical plane throughout the workspace. Key components like the chip heads, feed module anvils, spike rolls and band saw blades are precisely aligned for plumb, straightness and centerline using the jig transit. You can complete real-time measurements and adjustments with a precision scale that mounts to each machine component (Figure 2).

Other components in a sawmill must be level to operate properly. The jig transit also sweeps precise horizontal planes to level rollers and machine ways (Figure 3).

Jig transits and their related accessories are a natural fit in a sawmill environment. There are no wires to break or trip over, no worries about wind, light, temperature or humidity affecting results. The optical alignment technique described here provides all required measurements quickly and accurately in one set-up.

Brunson has everything sawmill teams need for optical alignment:

|

|