Use two target points to define a line

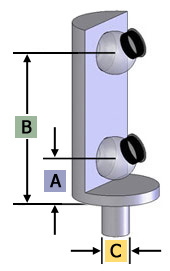

The 0.5THV Series creates a vector by using two target locations, precisely on the centerline of the adapter. Using most any software, it is easy to locate the point on the centerline of the shank which lies on the surface of the object being measured. This adapter may be used to create vector lines to evaluate "remote" target points (e.g., a critical point downrange on a hinge line). It is also handy when you suspect that the target hole may not be drilled square to the surface.

Refer to the part number configuration information below. Pick a low offset, a high offset, and a shank diameter which specifies your desired item. For example, 0.5THV-.375-.750-.25.

Note: We cannot show all possible options - if you don't see exactly what you want, make up your own part numbers using the configuration information below.

Part Number Construction:

| Low Offset | Value "A" | High Offset | Value "B" | Shank Diameter | Value "C" |

| 0.3125" | .3125 | 0.750" | .75 | 1/8" | .125 |

| 0.375" | .375 | 1.000" | 1 | 1/4" | .25 |

| 0.500" | .5 | 1.250" | 1.25 | 3/8" | .375 |

| 0.625" | .625 | 1.500" | 1.5 | 1/2" | .25 |

| 8 mm | 8MM | 2.00" | 2 | 3/4" | .75 |

| 10 mm | 10MM | 25 mm | 25MM | 4 mm | 4MM |

| 12 mm | 12MM | 30 mm | 30MM | 6 mm | 6MM |

| 14 mm | 14MM | 40 mm | 40MM | 8 mm | 8MM |

| 16 mm | 16 | 60 mm | 60MM | 10 mm | 10MM |

| You Specify | Note 1 | You Specify | Note 2 | You Specify | Note 3 |

| Note 1: Minimum value for A (low offset) is 0.3125" or 8 mm. Note 2: Maximum value for B (high offset) is 2.875" or 73 mm. Not all high offsets are compatible with all low offsets, check with us if you have a question. Note 3: Minimum shank diameter is 0.100" (3 mm). Maximum shank diameter is 0.750" (19 mm). |

|||||

May Be Used With

Any 0.5" diameter SMR

| Diameter in | 1" |

|---|---|

| Diameter mm | 25.4 mm |

| Hardness | HRC 42-45 |

| Material | Stainless Steel |

| Offset Tolerance | ±0.0005" (±0.013 mm) |

| Shank Diameter Tolerance | -0.0001" to -0.0005" (-0.003 mm to -0.013 mm) |